Cautions for Installation and maintenance of ball valve.

According to the construction, usually we can divide floating ball valve, trunnion ball valve, elastic ball valves and oil seal ball valve; if according to flow channel, it can be divided into straight-through ball valve, angle-through ball valve and three way ball valve. Three-way ball valve can be divided into T-shaped and L-shaped two kinds. According to the connection ends, it can be divided into the threaded connection ball valve, flange connection ball valve and welded ball valve three types.

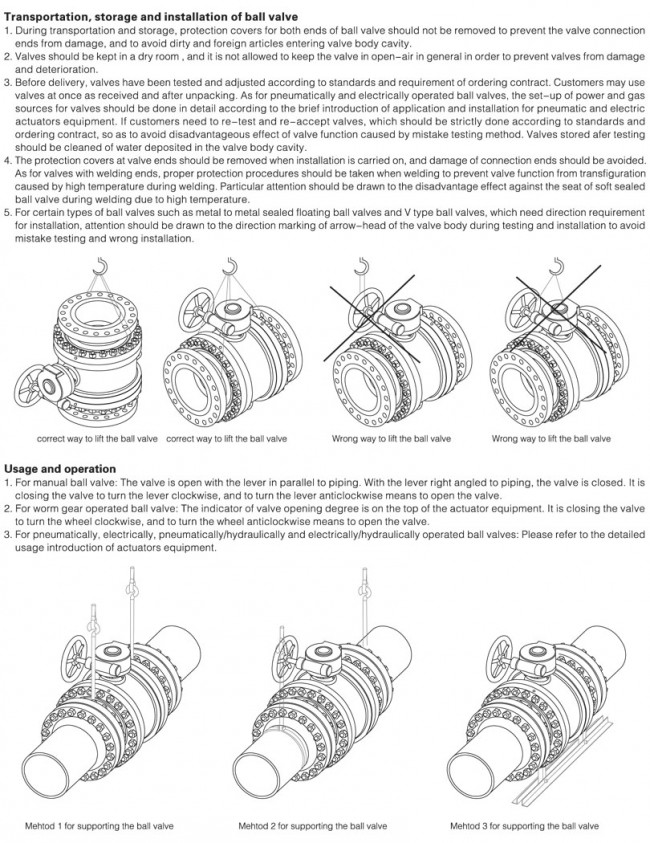

The ball valve installation and maintenance should note the following:

1. to leave the space of rotary position for valve actuator.

2. it can not be used for throttling action.

3. It should be installed upright if the valves are actuated operated.

Nominal pressure: PN1.0-32.0MPa, ANSI CLASS 150-2500, JIS10-20K

Nominal diameter: DN6 ~ DN1400, NPS 1/4” ~ 56”

Connections: flange, butt welded, threaded, socket welding, etc.

Applicable Temperature: -196 ℃ ~ 540 ℃ Driving mode: Manual, worm gear, pneumatic, electric, hydraulic, pneumatic, electro-hydraulic linkage.

Body material: WCB, ZG1Cr18Ni9Ti, ZG1Cr18Ni12Mo2Ti, CF8 (304) CF3 (304L), CF8M (316), CF3M (316L), Ti. If we choose different materials, it can be separately applied to water, steam, oil, nitric acid, acetic acid, the oxidizing medium, urea and other media.

info@welcovalve.com

info@welcovalve.com TEL: 86-577-67279881

TEL: 86-577-67279881 FAX: 86-577-67279880

FAX: 86-577-67279880 +86-15067717767

+86-15067717767 Skype: welcovalve

Skype: welcovalve