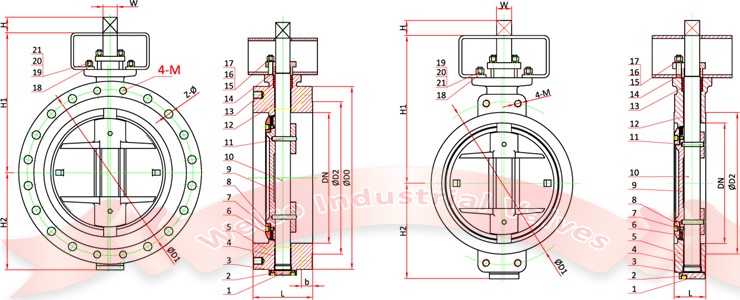

An Overview of D343H butterfly valve and D373H butterfly valve

D343H butterfly valve is wormgear operated, double flange, three eccentric (triple offset) metal seal structure butterfly valve. The seal is in the form of metal to metal, metal seals can be composited stainless steel and graphite combined sealing. It can be available manual, electric, pneumatic, hydraulic actuators etc.

D373H butterfly valve is wormgear operated, wafer type, three eccentric (triple offset) metal seal structure butterfly valve. The seal is in the form of metal to metal, metal seals can be composited stainless steel and graphite combined sealing. It can also be available manual, electric, pneumatic, hydraulic actuators etc.

And please pay attention to the flow questions for D343H butterfly valve and D373H butterfly valve when the valves are working in project:

1, We know the sealing ring are graphite and stainless steel SS304 composited material that is fixed in the valve disc. The disc is normally open status, the media will crash the sealing surface at the front erosion of seal ring, this will affect the sealing performance.

2. the structural limit, usually it is not suggested for below diameter DN200 valve, because the overall structure of the disc is too thick and the flow resistance is large.

3. Due to the principle of eccentric structure, the sealing surface of the valve plate and valve seat seal on the transmission of torque to the valve plate pressure to the valve seat. When it is in right flow status, the pressure is higher, the sealing is tigher. But when it is in reverse flow medium with media pressure, the seal may start to leak when the reverse pressure is back to the disc. So some customers ask us to design it bi-directional seal for triple offset butterfly valve. Usually it is single direction seal if not requested by customer.

D343H butterfly valve and D373H butterfly valve is widely used in water supply system, foodstuff, beverage, pharmaceutics, boiler, oil refining, chemical machinery industries, chemical and petrochemical processing, power generating plants, pulp and paper manufacturing processing, desalination, steelmaking, coal and mining industries. Size range from 2" to 120", pressure range from Class 150Lbs to Class 600Lbs.

info@welcovalve.com

info@welcovalve.com TEL: 86-577-67279881

TEL: 86-577-67279881 FAX: 86-577-67279880

FAX: 86-577-67279880 +86-15067717767

+86-15067717767 Skype: welcovalve

Skype: welcovalve